Countertop Finishes

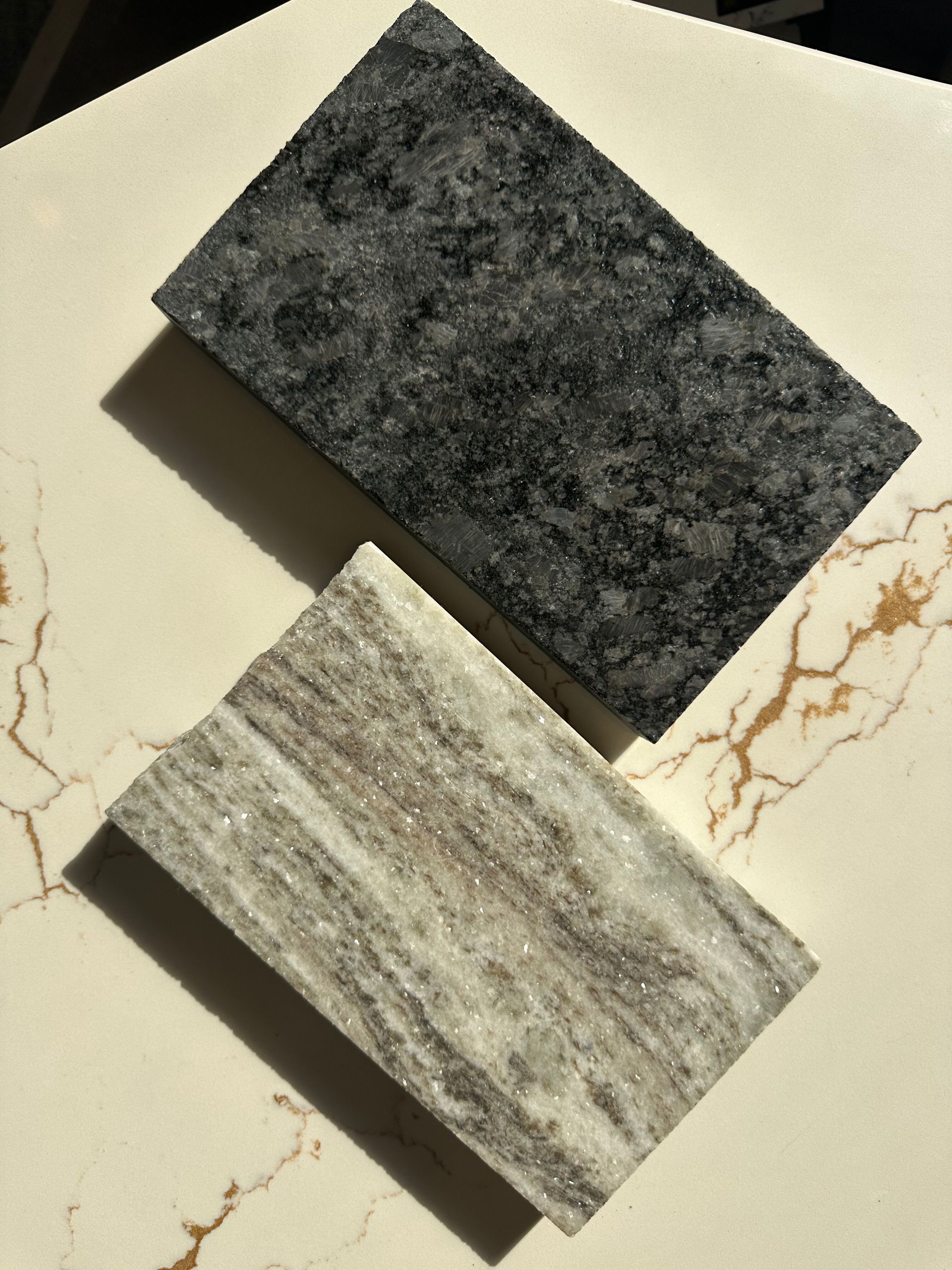

The Different Types of Finishes for Granite and Quartzite: Polished, Leathered, and Honed

When it comes to choosing the right countertop material for your kitchen or bathroom, granite and quartzite are two of the most popular natural stone options. Known for their beauty, durability, and timeless appeal, both materials come in a range of finishes that can dramatically affect the look, feel, and maintenance of your surfaces. Whether you're renovating your kitchen or adding a bathroom vanity, understanding the different types of finishes—polished, leathered, and honed—will help you make an informed decision that best suits your style and lifestyle.

In this blog post, we’ll take a closer look at these three finishes, how they differ, and the pros and cons of each, so you can choose the best one for your space.

1. Polished Finish

The polished finish is the most common and popular option for both granite and quartzite countertops. When you choose a polished finish, the stone is buffed to a high-gloss shine, bringing out its natural colors, patterns, and textures. This finish highlights the stone's inherent beauty and depth, giving your countertop a luxurious, reflective surface that looks sleek and modern.

Pros of a Polished Finish:

- Shiny and Elegant: The high-gloss finish adds depth and vibrancy to the stone, making it appear rich and elegant.

- Easy to Clean: The smooth surface of a polished countertop makes it relatively easy to wipe away spills, crumbs, and stains. It’s also more resistant to liquid absorption, which means it is less likely to stain than honed or leathered finishes.

- Resistant to Bacteria: The smooth surface of a polished finish reduces the ability for bacteria and germs to penetrate the stone, making it more hygienic for kitchen use.

- Reflective: Polished stone reflects light, making it an excellent choice for smaller spaces that need a brighter, airier feel.

Cons of a Polished Finish:

- Shows Fingerprints and Smudges: While easy to clean, the reflective surface can show fingerprints, smudges, and water spots more easily, especially in high-touch areas.

- Can Be Slippery: The smooth, shiny surface can be slippery, making it a less ideal choice for some high-traffic areas or families with young children.

- Scratches Can Be Visible: While polished stone is quite durable, any surface scratches may be more visible on a polished finish due to the reflective nature of the stone.

Best For:

- Modern kitchens and bathrooms with a sleek, contemporary aesthetic.

- Homeowners who appreciate high-gloss, reflective surfaces that make a bold statement.

- Spaces where ease of cleaning and hygiene are priorities.

2. Leathered Finish

A leathered finish is a textured, matte surface that provides a more natural, tactile feel compared to polished granite or quartzite. The process involves honing the stone and then adding a texture that resembles leather, with a slightly raised, rugged finish. This finish creates a more subtle, low-sheen appearance that’s softer to the touch.

Pros of a Leathered Finish:

- Unique and Luxurious: Leathered stone has a sophisticated, rich appearance that adds a sense of luxury to any space. Its texture makes it stand out from more traditional finishes like polished or honed.

- Non-Slip Surface: The textured surface makes it less slippery than polished stone, making it an ideal choice for high-traffic areas, particularly in kitchens.

- Hides Smudges and Fingerprints: Unlike polished finishes, the matte texture of leathered granite and quartzite is less prone to showing fingerprints, smudges, or water spots. This can be especially helpful in busy areas like kitchens where surfaces are frequently touched.

- Conceals Stains: The leathered finish also hides minor scratches, stains, and imperfections better than polished surfaces, which can make it a more forgiving choice in high-use areas.

Cons of a Leathered Finish:

- Requires More Maintenance: Leathered stone is more porous than polished stone, which means it may require more frequent sealing to prevent stains or liquid absorption.

- More Prone to Etching: Leathered surfaces can be more susceptible to etching from acidic substances like lemon juice or vinegar, so extra care is needed in areas where such substances are used frequently.

- Can Feel Rough: While the texture gives it a tactile appeal, some people may find the feel of a leathered finish less smooth or more difficult to clean in terms of wiping away dirt or debris.

Best For:

- Homeowners seeking a unique, rustic, or natural appearance with a sophisticated, luxurious vibe.

- High-traffic kitchens or bathrooms that require a non-slip surface.

- People who prefer a low-sheen, matte finish that hides imperfections and is resistant to fingerprints.

3. Honed Finish

A honed finish gives granite or quartzite a smooth, matte appearance that is softer and less reflective than a polished finish. The stone is buffed with abrasives until it achieves a flat, satin-like surface. The honed finish preserves the natural stone’s character, showcasing its subtle variations in color and texture, but without the shine.

Pros of a Honed Finish:

- Subtle and Sophisticated: The matte surface has a more understated, soft aesthetic compared to the high-gloss shine of polished stone. This can be perfect for creating a more relaxed, elegant atmosphere in a room.

- Durable and Less Prone to Damage: A honed finish is less likely to show surface scratches or chips than polished granite or quartzite. The matte texture hides imperfections more effectively.

- Non-Slip: Like the leathered finish, honed countertops are less slippery, making them safer in kitchens and bathrooms, especially around sinks or high-traffic areas.

- Easy to Maintain: While honed surfaces do require sealing, they tend to be easier to maintain over time compared to leathered finishes, as they don’t absorb liquids as readily as polished stone.

Cons of a Honed Finish:

- May Show Stains More Easily: Because a honed surface is more porous than a polished one, it can absorb liquids more easily, making it more susceptible to staining. This means it often requires more frequent sealing.

- Less Gloss and Vibrancy: If you prefer the high-shine, vibrant look of polished granite or quartzite, the honed finish may feel too dull for your taste. It also won’t bring out the colors and veins of the stone in the same way.

- More Maintenance for Protection: Honed surfaces generally require more frequent sealing and care to protect against staining.

Best For:

- Homeowners who prefer a soft, matte finish with a more subtle, organic feel.

- Those who want a more durable surface with fewer visible scratches but are okay with periodic sealing to prevent staining.

- People who prefer a classic, timeless look over a highly polished or reflective surface.

Which Finish Is Right for You?

Choosing the right finish for your granite or quartzite countertops ultimately depends on your personal style, the amount of maintenance you’re willing to commit to, and the functional requirements of your space.

- Polished Finish is perfect for those seeking a high-gloss, elegant look that enhances the natural beauty and color of the stone.

- Leathered Finish is ideal for homeowners looking for a unique, tactile feel that’s also practical, as it hides smudges and scratches while providing a more natural, rustic aesthetic.

- Honed Finish is best for those who want a matte, soft finish that’s subtle, durable, and easy to maintain but doesn’t mind sealing the surface more frequently to protect against stains.

Consider your kitchen or bathroom design, lifestyle, and how much care you’re willing to put into maintaining your stone. No matter which finish you choose, granite and quartzite are both stunning, long-lasting options that can transform your space.

Share On: