What is Edging?

February 3, 2025

What is Edging? A Guide to Different Types of Edging for Your Granite Surfaces

Granite and quartz are some of the most popular materials for countertops, kitchen islands, vanities, and other surfaces. Known for its durability, versatility, and luxurious appearance, granite and quartz can elevate the aesthetic of any space. However, while their surface is often the star of the show, the edging – the border or trim around the stone – plays an equally important role in its overall look and functionality.

If you’re considering granite or quartz for your home, you might be wondering what "edging" refers to and why it's important. Let’s explore what edging is for granite, the different types of edges available, and how to choose the best one for your project.

What is Edging for Granite and Quartz?

Edging refers to the shape, style, and finish of the edges of your countertops or surfaces. While the slab itself is a smooth and polished surface, the edges can be customized to suit the style of your kitchen, bathroom, or other space.

Not only does the right granite edge contribute to the aesthetics of your design, but it also serves functional purposes. For instance, rounded edges can prevent injury from sharp corners, while more intricate edges can add a luxurious, custom touch. The type of edge you choose can also impact the maintenance and cleaning of the countertop.

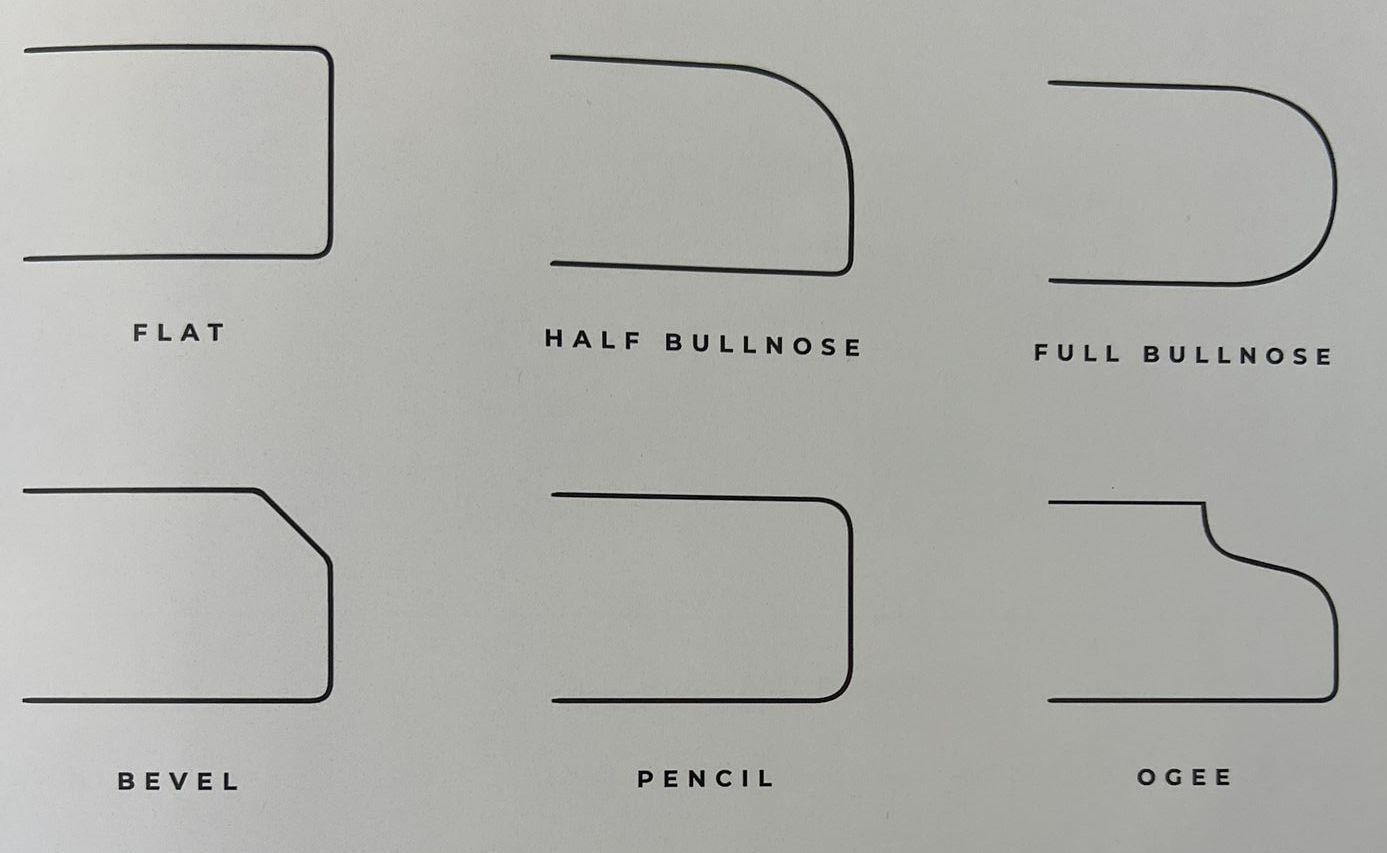

Different Types of Edging

There are several types of edges, ranging from simple, sleek lines to elaborate designs. The choice largely depends on your style preferences, the functionality you require, and the overall look you want to achieve for your space. Below are some of the most common types of granite edges:

- Straight Edge (Square Edge): A straight edge is one of the most basic and modern styles for countertops. As the name suggests, the edge is straight and sharp, offering a clean and minimalist look. This style works well in contemporary kitchens and bathrooms, where the focus is on sleekness and simplicity.

Pros: Simple and elegant, fits with almost any design style.

Cons: The sharpness of the edge may not be ideal for homes with young children or in high-traffic areas where accidents could happen.

- Pencil Edge: The pencil edge is another popular and simple choice for countertops. This style features a slightly rounded edge that’s similar to the straight edge, but with a gentler, more refined curve. The edge looks like the rounded tip of a pencil, hence the name. While the pencil edge is less ornate than more intricate designs like ogee or Dupont, it offers a clean, elegant look that complements both traditional and contemporary spaces.

Pros: It provides a minimalist yet polished appearance, making it versatile enough for almost any style and a safer choice for homes with children.

Cons: It is less decorative and might not stand out as much in larger spaces.

- Bullnose Edge: The bullnose edge is one of the most popular options for countertops. It has a smooth, rounded curve along the edge, giving it a soft and elegant appearance. Bullnose edges are particularly popular for kitchen counters and bathroom vanities because they are smooth to the touch and can handle a lot of wear.

Pros: Rounded edges are safer, soft to the touch, and easy to maintain.

Cons: Some may feel that it lacks the sharp, crisp lines that give a more modern feel.

- Half Bullnose Edge: This is a variation of the bullnose, where only the top portion of the edge is rounded, leaving the bottom edge square. The half bullnose offers a more subtle curve and combines the sleekness of a square edge with the softness of a rounded edge.

Pros: Easier to maintain than a full bullnose, provides a refined look that balances sharp and curved lines.

Cons: May not be as visually soft as a full bullnose for some design preferences.

- Bevel Edge: A bevel edge cuts the granite at a 45-degree angle, creating a slanted edge. This gives the granite a more contemporary look, and it can be especially effective for creating a more distinct, sharp profile. Beveled edges also make a space feel more streamlined.

Pros: Modern, sleek, and sharp appearance, great for a more geometric design.

Cons: More challenging to clean in the corners, especially if the angle is very steep.

- Ogee Edge: The ogee edge is a classic, elegant design that features an "S" shaped curve, often used in high-end kitchens and bathrooms. This style offers a more ornate, sophisticated look and can add a touch of luxury to your granite countertop.

Pros: Highly decorative, adds visual interest and depth to the countertop.

Cons: More complicated to fabricate, can be more expensive, and requires careful maintenance to avoid damage to the intricate curves.

- Chiseled Edge: A chiseled edge offers a rustic, natural look, often with rough, uneven edges that mimic the appearance of stone as it appears in nature. This style works well in kitchens or bathrooms with a more organic or natural aesthetic, such as farmhouse or rustic designs.

Pros: Unique and rustic, enhances the natural beauty of granite.

Cons: Requires more maintenance and is harder to clean due to its rough texture.

- Dupont Edge: The Dupont edge is a luxurious, thick edge that curves outward before coming back in. It’s known for its elegant and upscale look, making it popular in high-end home designs. This edge is often paired with thicker granite countertops.

Pros: Stylish and upscale, offers a bold statement.

Cons: More expensive and requires a thicker slab of granite, which can add to the cost.

Choosing the Right Granite Edge for Your Space

When selecting an edge for your granite countertops, consider the following factors:

- Style: The type of edge you choose should complement the overall design of your space. A modern kitchen may benefit from sharp edges like a straight or bevel edge, while a more traditional or rustic design may call for bullnose or chiseled edges.

- Safety: If you have young children, it’s advisable to avoid sharp, pointy edges like a straight edge. Rounded edges like the pencil, bullnose, or half bullnose can prevent injury from sharp corners.

- Maintenance: Some edges, such as beveled and ogee, may be harder to clean due to their intricate shapes. A simpler edge, such as an eased or straight edge, is much easier to maintain.

- Cost: More intricate edges, such as ogee or Dupont, may cost more due to the complexity involved in fabrication. Be sure to budget for the style that fits your desired aesthetic and your project.

Conclusion

Granite and quartz countertops are a timeless investment that can last a lifetime, and choosing the right edging is an important part of making your countertops both functional and beautiful. Whether you opt for the sleek lines of a straight edge, the elegance of a bullnose, or the bold statement of a Dupont edge, your countertop’s edge will impact the look and feel of your space.

By understanding the different types of edging available, you can make a more informed decision that will enhance both the aesthetics and usability of your countertops for years to come.

Granite is one of the most popular choices for kitchen and bathroom countertops—and for good reason. It's durable, beautiful, and timeless. But like any natural stone, granite needs a little care to keep it looking its best. One of the most important steps in maintaining granite countertops is sealing them. In this post, we’ll walk you through the basics of sealing granite, why it’s so important (especially for countertops that get regular use), and how MGL Granite can help. Why Does Granite Need to Be Sealed? Granite is a natural stone with a porous surface. That means that if it's left unsealed, liquids like water, oil, wine, or juice can seep into the stone, causing stains or even long-term damage. Bacteria can also find their way into those tiny pores, which isn’t something you want on your food prep surfaces. Sealing your granite countertops helps create a protective barrier that: Repels moisture and spills Prevents staining Makes cleaning easier Extends the life and beauty of your countertops How Often Should You Seal Granite? It depends on the type of granite, how much use your countertops get, and the type of sealer used. Some granite varieties are denser and require sealing less often, while others are more porous and need more frequent attention. As a general rule: Seal high-use kitchen countertops once a year. For less frequently used areas (like guest bathrooms), every 2–3 years may be enough. Pro Tip: Not sure if it's time to reseal? Drip a few drops of water on the surface. If it beads up, you're good. If the water soaks in, it's time to reseal. How to Seal Granite Countertops: Step-by-Step 1. Clean the Surface Thoroughly: Wipe down your granite with a gentle stone cleaner or warm soapy water. Remove all residue and let it dry completely before sealing. 2. Choose the Right Sealer: Use a granite-specific penetrating (or impregnating) sealer that soaks into the stone to provide long-lasting protection. 3. Apply the Sealer: Follow the instructions on the label. Typically, you'll a pply the sealer evenly with a clean cloth or applicator pad. Let it absorb for about 15–20 minutes. Wipe off any excess with a clean, dry cloth 4. Let It Cure: Most sealers cure within 24 hours. During this time, avoid using the surface or getting it wet. Want a Professional to Handle It? We've Got You Covered! At MGL Granite, we don’t just install granite—we help you maintain it. We offer professional granite sealing services, so you don’t have to worry about the mess or guesswork. Whether you need sealing for a newly installed countertop or want to refresh an older surface, we’re here to help. Keep Your Granite Looking Great for Years Sealing your granite countertops is a simple step that goes a long way in protecting your investment. With regular maintenance—or a visit from our team—you can enjoy the beauty and durability of your countertops for decades to come. Contact us today to schedule your sealing service or ask about the best care plan for your countertops!

Share On: