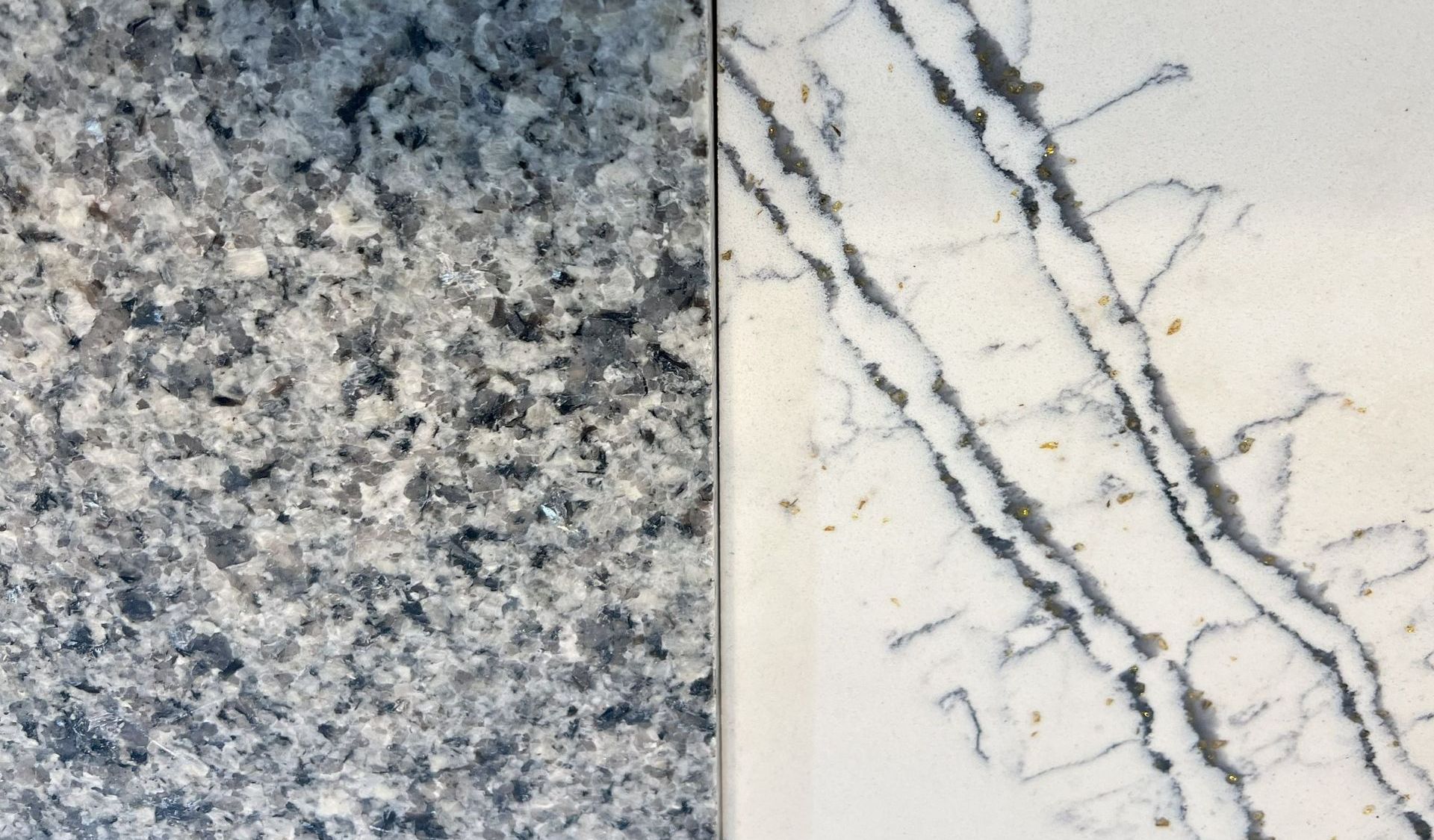

Granite vs. Quartz Countertops

January 28, 2025

Granite vs. Quartz Countertops: Which One is Right for Your Home?

When it comes to upgrading your kitchen or bathroom, choosing the right countertop material is one of the most important decisions you'll make. Among the most popular options are granite and quartz countertops. Both are beautiful, durable, and high-end materials, but they have distinct differences that may sway your decision. In this post, we'll compare granite countertops versus quartz countertops, examining their pros and cons to help you decide which one is the best fit for your home.

Cons of Quartz Countertops

Granite Countertops: Nature's Beauty

Granite is a natural stone that is cut from quarries, then polished and finished for use in your home. Each granite slab is unique, showcasing stunning patterns and vibrant colors that come straight from nature.

Pros of Granite Countertops

- Durability: Granite is one of the hardest natural stones, making it incredibly durable. It’s resistant to scratches, chips, and cracks, which is ideal for high-traffic kitchens and busy households when properly maintained.

- Heat Resistance: Granite countertops can withstand high temperatures, meaning you can place hot pots and pans directly on them without worrying about damage.

- Unique Aesthetic: Every granite slab is one of a kind. The variations in color and pattern give your countertop a unique, personalized touch. If you want something truly distinctive, granite is an excellent option.

- Long-lasting Investment: When properly maintained, granite countertops can last a lifetime. This makes them a worthwhile investment for any home.

- Increase Home Value: High-end materials like granite add value to your home, which can be especially beneficial if you're looking to sell.

Cons of Granite Countertops

- Porous Surface: While granite is generally resistant to stains, it’s still a porous material. Spills, especially from acidic substances like wine or citrus juice, can seep into the surface if not wiped up quickly. Sealing your granite countertop regularly can help prevent this, but it’s an extra maintenance step.

- Cost: Granite is on the expensive side. Prices vary depending on the color and quality of the slab, but generally, it’s a higher-cost material compared to other options.

- Heavy Material: Granite is quite heavy, which can make installation more complicated and expensive. It also requires proper support to avoid damage to it or your home.

- Limited Color Range: Although beautiful, the color options are somewhat limited compared to quartz. If you’re looking for a specific shade or pattern, granite might not always offer what you want.

Quartz Countertops: Engineered for Perfection

Quartz countertops are engineered stone products made from a blend of natural quartz crystals and resins. This composition allows for a wide range of colors, patterns, and finishes that are consistent across the entire surface.

Pros of Quartz Countertops

- Low Maintenance: Unlike granite, quartz countertops don’t need to be sealed because the resins used in their creation make them non-porous. This means you don’t have to worry about stains from spills or food.

- Consistent Look: If you're aiming for a countertop with a uniform color or pattern, quartz is the way to go. The engineered nature of quartz means every slab looks identical, providing a sleek and contemporary appearance.

- Durability: Quartz is also highly durable, though slightly softer than granite. It resists scratches, chips, and cracks well, though not as strongly as granite. It’s also heat-resistant, though you may still want to use trivets or hot pads to protect the surface.

- Wide Variety of Colors and Designs: Quartz countertops come in a broad range of colors and patterns, including designs that mimic natural stone like granite or marble. This gives you more design flexibility and creative freedom in your kitchen or bathroom remodel.

- Eco-Friendly Options: Some brands of quartz countertops use recycled materials in their manufacturing process, making them a more eco-conscious choice compared to granite.

Cons of Quartz Countertops

- Not as Heat Resistant: While quartz can handle normal kitchen heat, it’s not as heat-resistant as granite. Placing extremely hot pots and pans directly on quartz may cause discoloration, surface damage, or warping.

- Not Scratch-Proof: Although quartz is tough, it’s not completely scratch-proof. Sharp knives or rough handling can leave marks on the surface, so it's recommended to use cutting boards and avoid dropping heavy objects.

- Artificial Look: Some homeowners prefer the natural look of granite, as the patterns in quartz are created during the manufacturing process. While there are beautiful quartz options, the aesthetic might not appeal to those who want something that feels purely organic and natural.

- Cost: Like granite, quartz countertops can be expensive, especially for premium options with intricate patterns or colors. However, prices can vary based on brand, color, and installation costs.

How to Choose Between Granite and Quartz

Both granite and quartz offer incredible benefits, but the choice between them ultimately depends on your priorities and lifestyle. Here are a few things to consider when making your decision:

- Maintenance: If you prefer a low-maintenance countertop that doesn’t require sealing, quartz is the better option.

- Aesthetic: If you're drawn to natural stone and want a one-of-a-kind look with rich variations, granite is perfect. However, if you prefer a more consistent and customizable appearance, quartz offers a wider range of designs.

- Durability: Both materials are durable, but granite is more heat-resistant and scratch-resistant. If your kitchen sees a lot of cooking activity, granite might hold up better in the long run.

- Budget: Both options can be pricey, but quartz generally offers more affordable options than high-end granite. However, premium quartz can still exceed the price of budget-friendly granite.

Conclusion

In the granite vs. quartz debate, there’s no clear "better" option; it really depends on your needs. If you want the durability and beauty of natural stone, along with a one-of-a-kind pattern, granite is a fantastic choice. If you prefer a low-maintenance, consistent surface with a wide variety of colors and patterns, quartz is your best bet.

Ultimately, the decision comes down to what works best for your kitchen, your lifestyle, and your budget. Both materials will elevate your space, so you can’t go wrong with either one!

Marble has long been admired for its beauty, making it a popular choice for countertops and vanities in both kitchens and bathrooms. From its timeless appeal to its unique patterns, marble adds an elegant touch to any space. But have you ever wondered how this stunning stone forms? Let’s explore the geological journey of marble and its role in creating beautiful surfaces. What is Marble? Marble is a metamorphic rock that forms when limestone undergoes a transformation process under heat and pressure deep within the Earth’s crust. Over millions of years, this change alters the composition of limestone, resulting in a denser, crystalline stone with unique patterns and colors. The final product, marble, is often celebrated for its aesthetic qualities, making it a preferred material for interior design, especially in kitchens and bathrooms. The Journey from Limestone to Marble The Precursor: Limestone Marble begins as limestone, a sedimentary rock primarily composed of calcium carbonate (CaCO₃). Over millions of years, limestone forms from the accumulation of marine organisms, like shells and corals, as well as from the precipitation of minerals from water. While limestone itself is beautiful, it is softer and more porous compared to marble. Heat and Pressure: The Metamorphic Transformation As limestone is buried deep within the Earth due to tectonic plate movements, it is subjected to high pressure and temperature. These conditions cause the calcium carbonate crystals in the limestone to recrystallize. The result is marble—denser and more compact than its limestone predecessor. The stone’s texture and structure are transformed, creating the unique crystalline appearance that marble is known for. The Role of Impurities One of the defining features of marble is its distinctive veining and color variations. These patterns are a result of impurities in the original limestone. As the limestone undergoes metamorphism, minerals such as iron, clay, and sand mix with the calcium carbonate, creating different colors and patterns. For example, the presence of iron may give the marble a reddish or brownish hue, while other minerals can contribute shades of gray, green, or black veining throughout the stone. Time and Earth's Forces Over millions of years, geological processes like tectonic shifts and erosion can bring marble closer to the Earth’s surface. Once exposed, it can be mined and processed into slabs, tiles, and other shapes to be used in various applications, including countertops and vanities. The marble’s natural beauty, shaped by its long journey, becomes a defining feature of any space. Why Marble is a Popular Choice for Countertops and Vanities Aesthetic Appeal Marble’s most striking feature is its unique appearance. Each piece of marble has its own distinct veining, color, and pattern, making it a highly sought-after material for countertops and vanities. Whether it’s the classic white of Carrara marble or the dramatic veining of dark-colored varieties, marble adds elegance and sophistication to any room. Timeless Elegance Marble has a long history, having been used in ancient architecture, sculptures, and monuments. Its timeless elegance makes it a perfect addition to both modern and traditional home designs. Whether you’re creating a sleek, contemporary kitchen or a luxurious, classic bathroom, marble complements a wide variety of styles. Variety of Options One of the benefits of marble is its wide range of color and pattern variations. From soft, neutral tones to bold, dramatic veins, there is a marble variety to suit any taste. Popular marble varieties for countertops include Carrara, Calacatta, Statuario, and Emperador, each with its unique characteristics and beauty. Conclusion The formation of marble is a fascinating natural process that takes millions of years, from the transformation of limestone under heat and pressure to the final crystallization that gives the stone its iconic look. Whether you’re using it in a countertop, vanity, or other design element, marble’s beauty, with its one-of-a-kind patterns and colors, will continue to be a favorite in interior design. With proper care, marble surfaces can last for many years, providing timeless elegance to any space.

Share On: